RSV-RF Single Duct VAV Terminals

| PRODUCT INFORMATION & FEATURES | |

| MODEL | ROYAL SERVICE Single Duct CAV VAV Terminals |

| TYPE | Constant / Variable Air Volume Control Air System |

| APPLICATION | ♣ Air Conditioning ♣ Heating ♣ HVAC Systems ♣ Ventilation ♣ Noise and Attenuation |

| FEATURES | ♦ Superior air distribution ♦ Easily adapts to office changes ♦ Lower cost per zone ♦ Reliable and durable quality ♦ Easy maintenance ♦ Automation control capabilities ♦ High Perform Premium Quality |

| APPLICATION SCENARIOS | HOTEL, villa, APARTMENT, OFFICE BUILDING, HOSPITAL, school, mall, Sports venues, Leisure Facilities, supermarket, WAREHOUSE, WORKSHOP, Park, farmhouse, Courtyard, closed or open offices, libraries, meeting rooms, exhibition halls, shopping markets, rest rooms, banquet halls etc. |

| HOUSING/CASING | Galvanized Steel |

| INLET DIAMETERS | 5’’ to 16’’ (175 to 403mm) |

| AIR FLOW RANGES | 59 to 4200 CFM (0.03 to 1.98m3/s) |

| SHAPE OPTION | Round, Square, Rectangular |

| WARRANTY | 1 Years |

| CONTROL | Pneumatic Analog Digital Control |

| OPTION | Pressure Independent, Pressure Dependent |

| KEY WORDS | Air handling unit, Air Valve, Air Damper, Air Regulator, Volume Control, Air Distribution, Air Diffuser, Air Terminal Units Box, VAV, CAV, HVAC |

| OEM & ODM SERVICE | ACCEPTABLE, please send us your requirements |

Structure Specifications & Characteristics:

RSV single duct VAV terminals are to be constructed of mechanical and control components. The mechanical components are composed of attenuator box casing velocity sensor, damper, hangers, control enclosure, internal insulation, and hot water reheat coils or electric reheat, plenum, and sound attenuator. The control components are composed of disconnect switch, fuse, terminal block, transformer controller, actuator, thermostat.

♦ Attenuator Box Casing

The box casing is to be constructed of high quality 22 gauge/0.8mm galvanized steel, internally lined with 48k/m3 fiber-glass insulation covered with erosion resistance black matted material, manufactured to have two functions, first insulation and second sound attenuation. The box casing outlet is sturdy, constructed and sealed with metal and suitable for field slip and drive or flange ductwork connections.

Leakage of the box casing is not to exceed 1% at inlet static pressure of 4 in wg/1000P.

♦ Velocity Sensor

The Royal cross flow sensor with multi-points amplifies velocity pressure signals for a transvers air flow measurement.

It’s accurate design to ensure minimum pressure drop and sound levels. Optional, linear flow sensor is available

Aluminum and plastic construction provide long durable operation.

♦ Damper

The maintenance free AV damper is constructed with a gasket sandwiched between two 18 gauge/1.2mm galvanized sheet metal secured to a carbon steel shaft The shaft is construction of carbon steel. Both gaskets and seals are designed for cool temperature and to minimize shaft seals heat transfer. Damper shaft is sealed to the casing with a plastic nylon bearing.

Leakage of damper is not to exceed 1% at inlet static pressure of 4 in wg/1000pa

♦ Control Enclosure(Optional)

The control enclosure is made of high quality 2 gauge/. mm galvanized steel With multiple wire conduit opening,

it is convenient for control elements installation and wiring. This control enclosure can be ordered for all VAV controllers.

Designed for NEMA(2)

♦ Hot Water Reheat Coils(Optional)

Hot water reheat coils shall be enclosed in a minimum 20 gauge/0.9 mm galvanized steel casing with slip and drive construction for attachment to metal ductwork. Coils shall have optional factory installed on the terminal discharge.

Aluminum fins, 0.005 inch / 0.13 mm thick, 10 per inch shall be rippled Fins are mechanically bonded to copper tubes.

Coil have 1/2 inch O D. copper tubes, 0.016 thick wall. 1/2 or 7/8 inch male solder header connections. Coils shall be leak tested to 300 psi and maximum working pressure 240 psi at maximum 200 degree water. Number of coil rows and circuits shall be selected to provide performance as required per the plans.

♦ PTC Type Black Electric Reheat Coils(Optional)

The RSV-TU-I series standard electric heater is manufactured by Royal Service, specifically designed and tested for use with VAV/CAV terminal units. The electric heater install as factory mounted and tested terminal or shipped separately with a slip &drive or flanged construction.

Elements shall be positive temperature coefficient(PTC).

Terminal integrated elements shall be housed in a casing with variable insulation options and as a section be integral with the terminal Elements are designed to set downstream 6150mm-10/250 mm(depended on local codes)from the discharge Installed at the factory to prevent damage during transportatiorand installation From the discharge

Installed at the factory to prevent damage during transportatiorand installation PT C heaters are resistance device and maintain maximum thermal transfer and element life by reducing energy when air flow is reduced. Wired and designed with the electrical elements in balanced to ensure equal output in each step .

Control Panel, Attached and outside the reheat casing the control devises shall be housed in a NEMA 1 enclosure with knock outs for power wiring, with or without a hinged access door for access to all controls and safety devices. Black heater shall not glow red when power is applied and air flow is zero or at any given flow. The Heater will modulate automatically according to flow of air across the element providing uniform heating output without staging.

♦ Electric heat(Optional)

Standard primary automatic high temperature reset thermal cutout, and secondary manual reset thermal cutout, Optional safety devices include duct static pressure airflow sensor for proof of flow to stop heating with no airflow, integral door interlock type disconnect switch which will not allow the access door to be opened while power is on, fused or circuit breaker in-line terminal block.

Control options with SCR control device to control the heaters elements and shall deliver maximum heating when needed. when controlled by the air terminal controller.

SCR optional input signals. Variable voltage signal 0-10 VDC Pulse width modulation AC or DC.

♦ Nickel Chrome Type Electric Heat(Optional)

Electric coils shall be manufactured for installation options as separate or on the terminal by the terminal manufacturer.

Slip Drive type connection Terminal integrated coils shall be housed in a casing with variable insulation options and as a section be integral with the terminal Elements are designed to set downstream 6150mm-10/250 mm( depended on local codes) Installed at the factory to prevent damage during ranspor ation and installation. 80/20 nickel chrome supported by ceramic isolators arranged in a staggered pattern to maintain maximum thermal transfer and element life.

Wired and designed with the electrical elements in balanced to ensure equal output per step Control Panel; Attached and outsie te reheat casing the conrol devises shall be used in a NEMA 1 enclosure with knock outs for power wiring, with or without a hinged access door for access to all controls and safety devices.

Standard primary automatic high temperature reset thermal cutout, and secondary manual reset thermal cutout, Optional safety devices include duct static pressure airflow sensor for proof of flow to stop heating with no airflow, integral door interlock type disconnect switch which will not allow the access door to be opened while power is on, fused or circuit breaker in-line terminal block.

Control options with SCR control device to control the heaters elements and shall deliver maximum heating when needed when controlled by the air terminal controller.

SCR optional input signals Variable voltage signal 0-10 VDC. Pulse width modulation AC or DC

Coils options include finned tube.

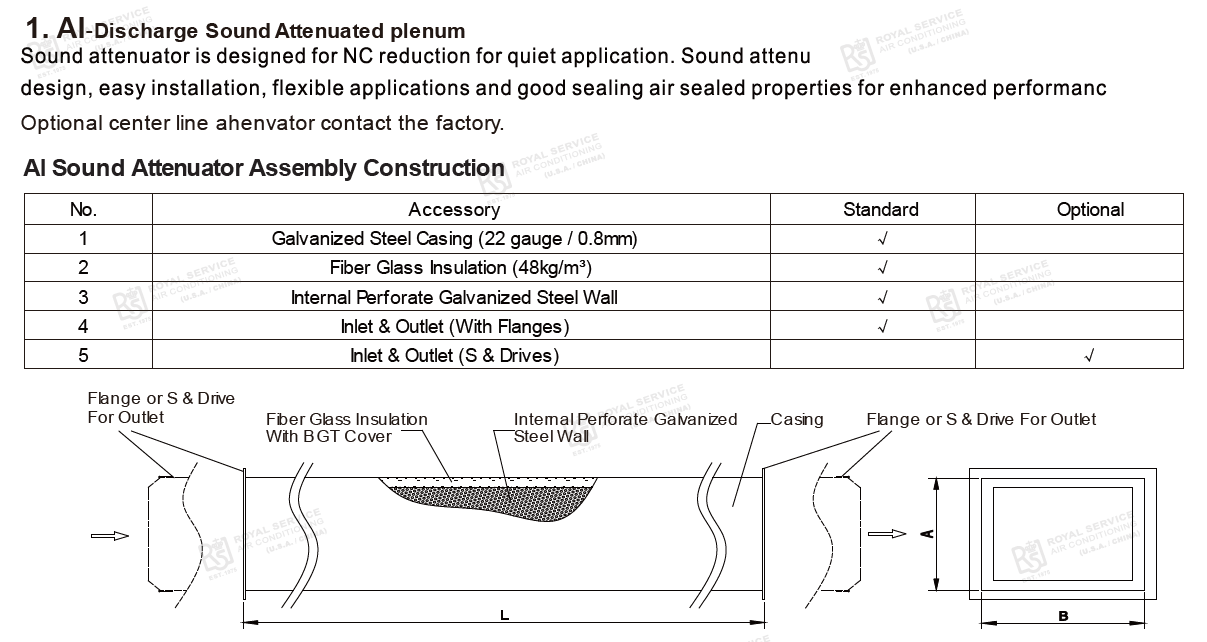

♦ Sound Attenuator Section (Optional)

Sound attenuator shall be provided in sound sensitive applications. Constructed with 21 gauge/0. 8mm sandwiched with two galvanized steel plates. High quality galvanized steel skin and internal material fiberglass insulation lined. Outlet and inlet connections slip and drive or flanged.

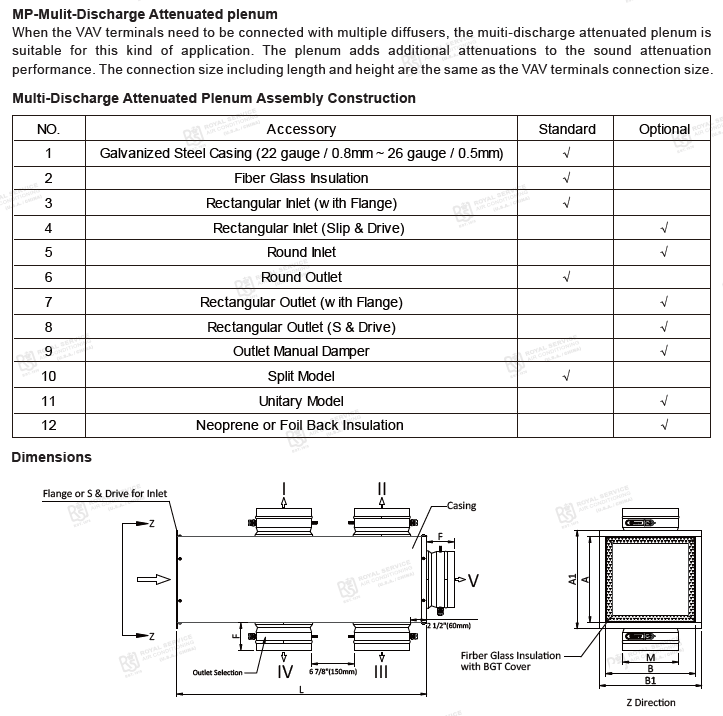

♦ Multi-outlet Plenum (Optional)

One of single duct terminal features is its flexibility of plan layout. Royal Service can provide standard modular plenum with multiple outlets or even customized. If it is used in a place where the sound level must be at a required level, plenum with lined sound attenuation material is also available in different composition with metal construction of 21 gauge/0. 8mm. 1/2 inch/12.7mm or 1/25mm insulation.

♦ Insulation (Optional)

Fiber ass with metal or metal mesh( M MM Insulation duct board with aluminum face(DAF), Closed cell black color flex(CC), Foil faced insulation(FFI)standard or scrim, and standard insulation.

(ML)perforated, or metal cover.

♦ UVC(Optional)

Installed at the factory or shipped separate, commercial building VC lighting in the TU air stream. Applications include medical office buildings, commercial meeting rooms, and Hotel meeting rooms.

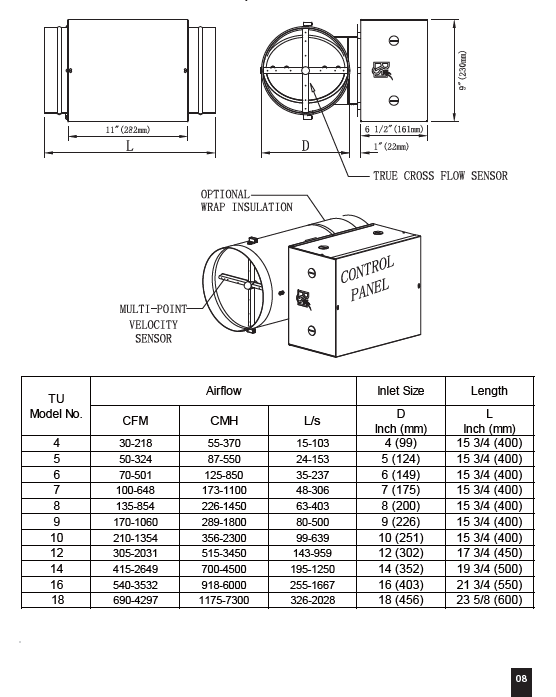

Round Retrofit Single Duct CAV VAV Terminals (RSV-RF)

• Suitable for Constant volume and variable volume systems.

• Convert existing constant volume systems or old mechanical regulator terminals to energy efficient variable volume operation.

• Suitable for different airflow system designs (Pressure independent/ Dependent).

• Suitable for different control application (Pneumatic / Analog / Digital control

• Designed for different system application (Cooling only / Cooling with reheat / Heating only).

• High quality galvanized steel, inlet flow measured with cross multi-point averaging sensor for pressure independent terminals.

Great air zone damper, solid construction, seamless welded round tube, double damper sealed for Off control

Add Control, 24volts, on-off, modulation, floating, zone or commercial systems,

Compared with other dampers this damper is designed for close off control. Countless operation

Match all zone controls with this damper for a better system.