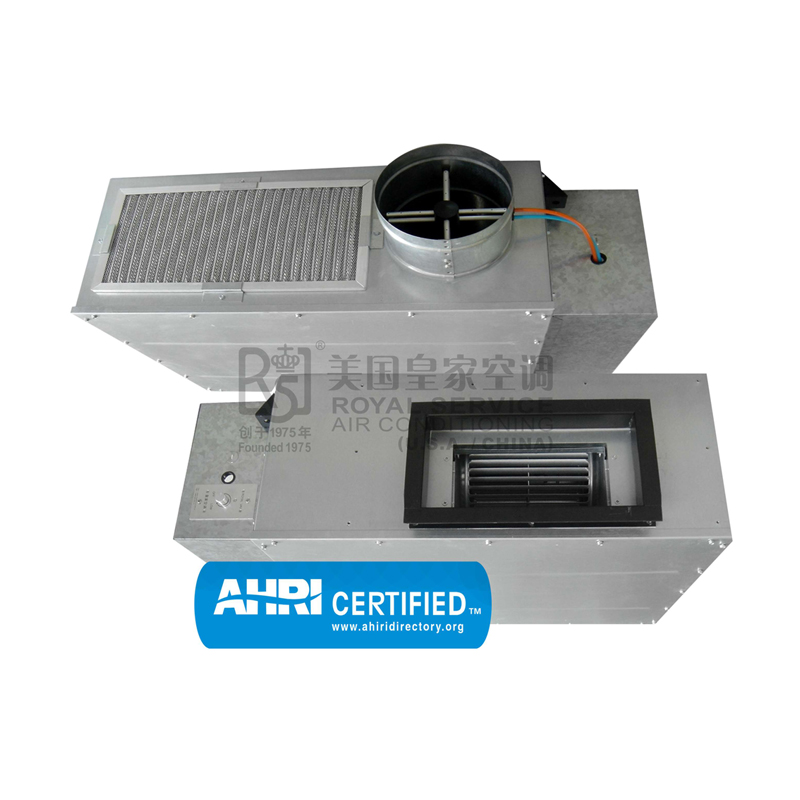

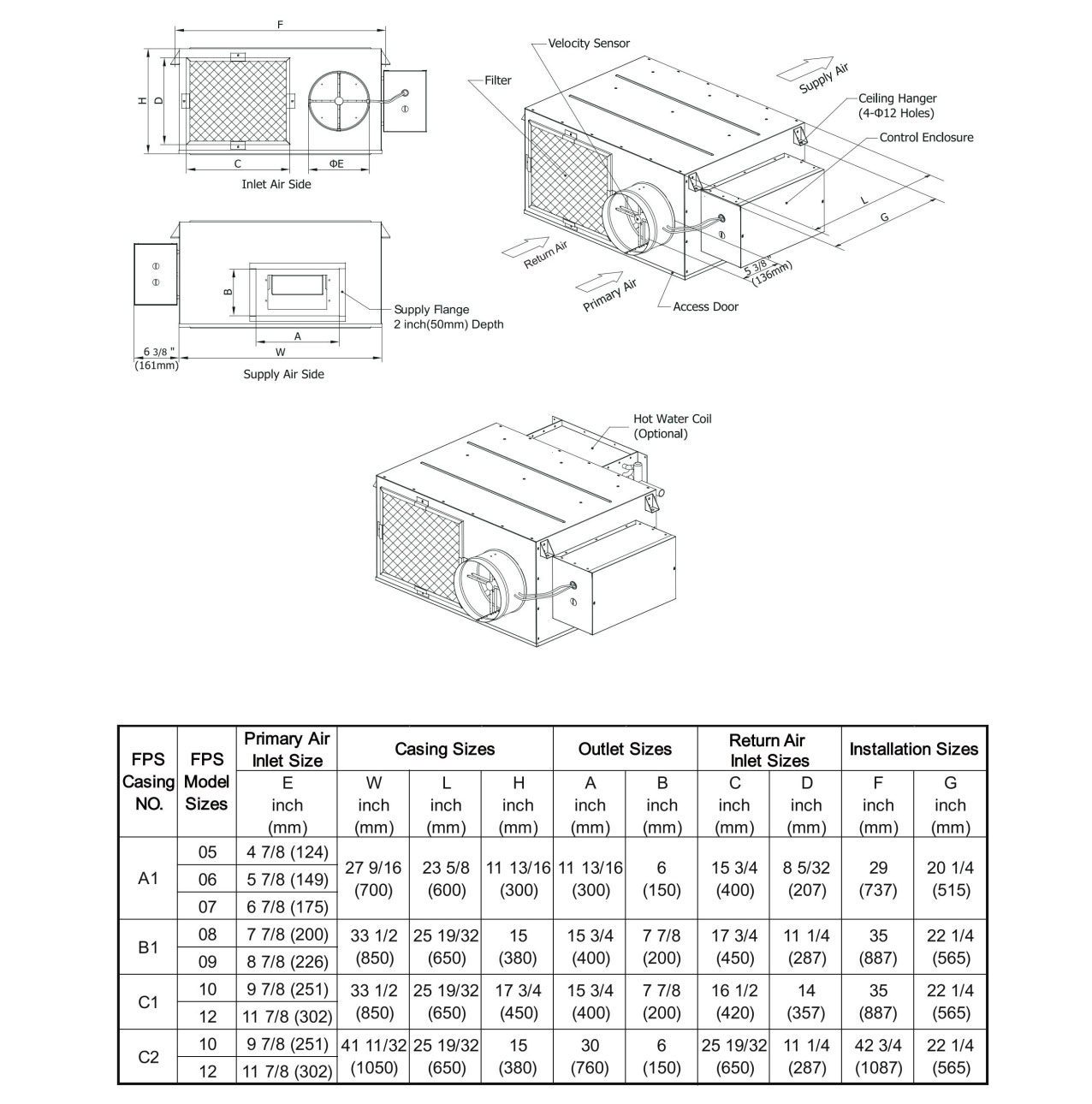

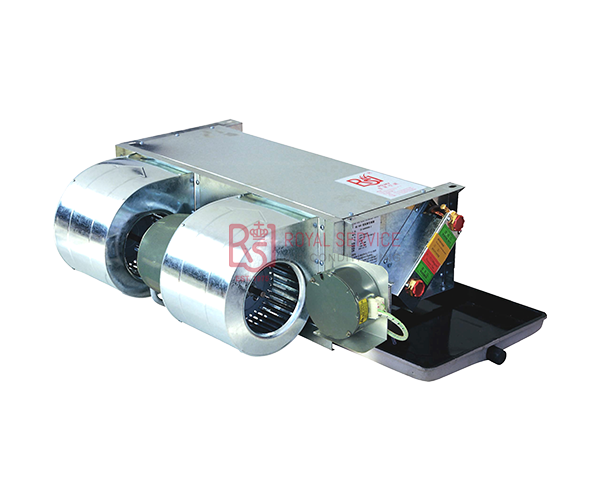

Fan Powered VAV Terminal (RSV-FPS Series)

• Designed to provide superior comfort control to zones.

• FPS Unit’s fan runs continuously to deliver constant airflow to a zone during occupied hours.

• Primary air damper controls the primary air into the terminal unit delivered through the

terminal’s fan.

• Ceiling plenum air is drawn through the return and mixed with primary inlet to supply air

temperature and improve zone air movement.

• Utilizes analog or direct digital control.

• PCB power board allows for quick installations.

• Available with an ultra-high efficiency ECM motor technology.

• Attenuated casing constructed with high quality galvanized steel insulated with batted covered

fiber-glass. Inlet flow measured with cross multi-point averaging sensor for pressure independent terminals. Uses high performing low leakage blade damper.

• AHRI certified, with additional 3rd-party testing at the National Center of Quality Supervision.

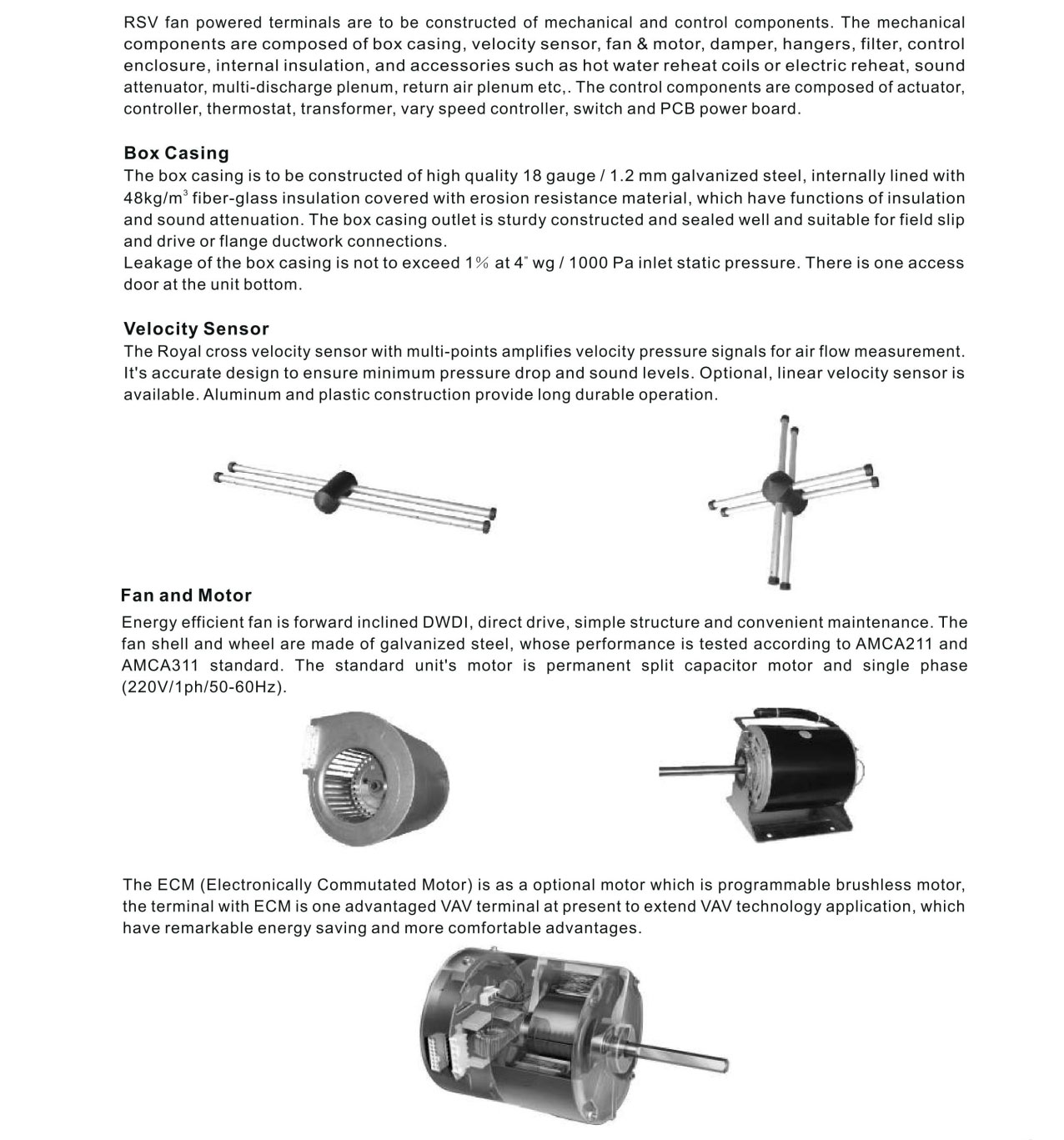

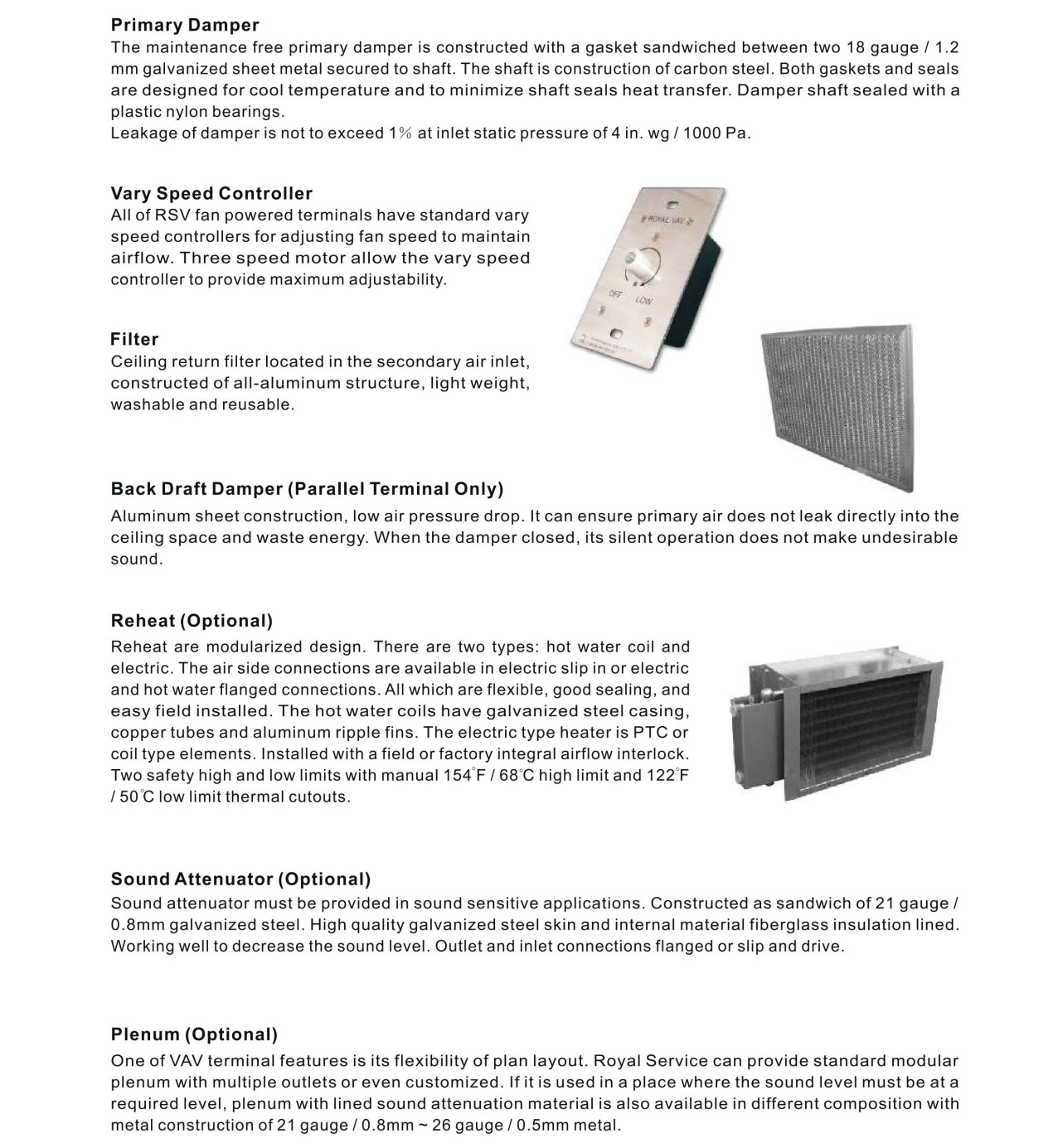

Brief Introduction

There are two basic structures of RSV fan powered terminals: series and parallel. Each contains fan with motor and variable air volume damper. For low temperature applications below 50F/10 C, please select Royal low temperature terminals at below 50F/10C supply air temperature.

In a series fan powered terminal, the fan is in the primary air stream and runs constantly after primary air, secondary air are mixed and pressurized.

At cooling mode, the zone thermostat throttles the primary air damper to change primary air flow, and the terminal fan makes up the difference by inducing more or less ceiling air. It provides a constant volume of air to the space regardless of load.

At heating mode, when the zone temperature is below the set point, primary air goes to a minimum ventilation setting, the terminal fan induces maximum ceiling air. If the zone temperature drops still further, the thermostat can energize optional heater to raise zone temperature by increase supply air temperature.

The series fan powered terminal is a constant volume, variable temperature and pressure independent control unit. Series unit fan must be adjusted to match the maximum primary air to ensure that the primary air does not exceed the fan airflow, as this would result in the short-circuiting of primary air into the ceiling space and waste energy. The pressure independent controller and inlet flow sensor control the primary air damper to compensate for changes in inlet static pressure and ensure design airflow is maintained.

In a parallel fan powered terminal, the fan sits outside the primary air stream and runs intermittently At cooling mode, the zone thermostat throttles the primary air damper (functioning as a single duct VAV terminal) to change primary air flow while the fan is stopped. At heating mode, the primary air may be set to a minimum position to ensure continuous ventilation, and the terminal fan becomes energized to induce ceiling air to raise zone temperature. If the zone temperature drops still further, the thermostat can energize optional heater, thereby raising discharge air temperature.

The parallel terminal unit is therefore variable volume and constant temperature at the cooling mode and essentially constant volume and variable temperature at the heating mode.