Fan Powered VAV Terminal (RSV-LFPS Series)

• Designed for handling low temperature (39'F to 50°F) air in VAV system.

• Thermal bridge designed at special points of the unit special lower temperature zone of unit. (new thermal material at damper's shaft to increase thermal diffusion)

• Unit's fan runs continuously, draw the ceiling plenum air into unit to raise supply air temperature to eliminate the risk of condensed water at the diffusers face

• Improved zone air movement.

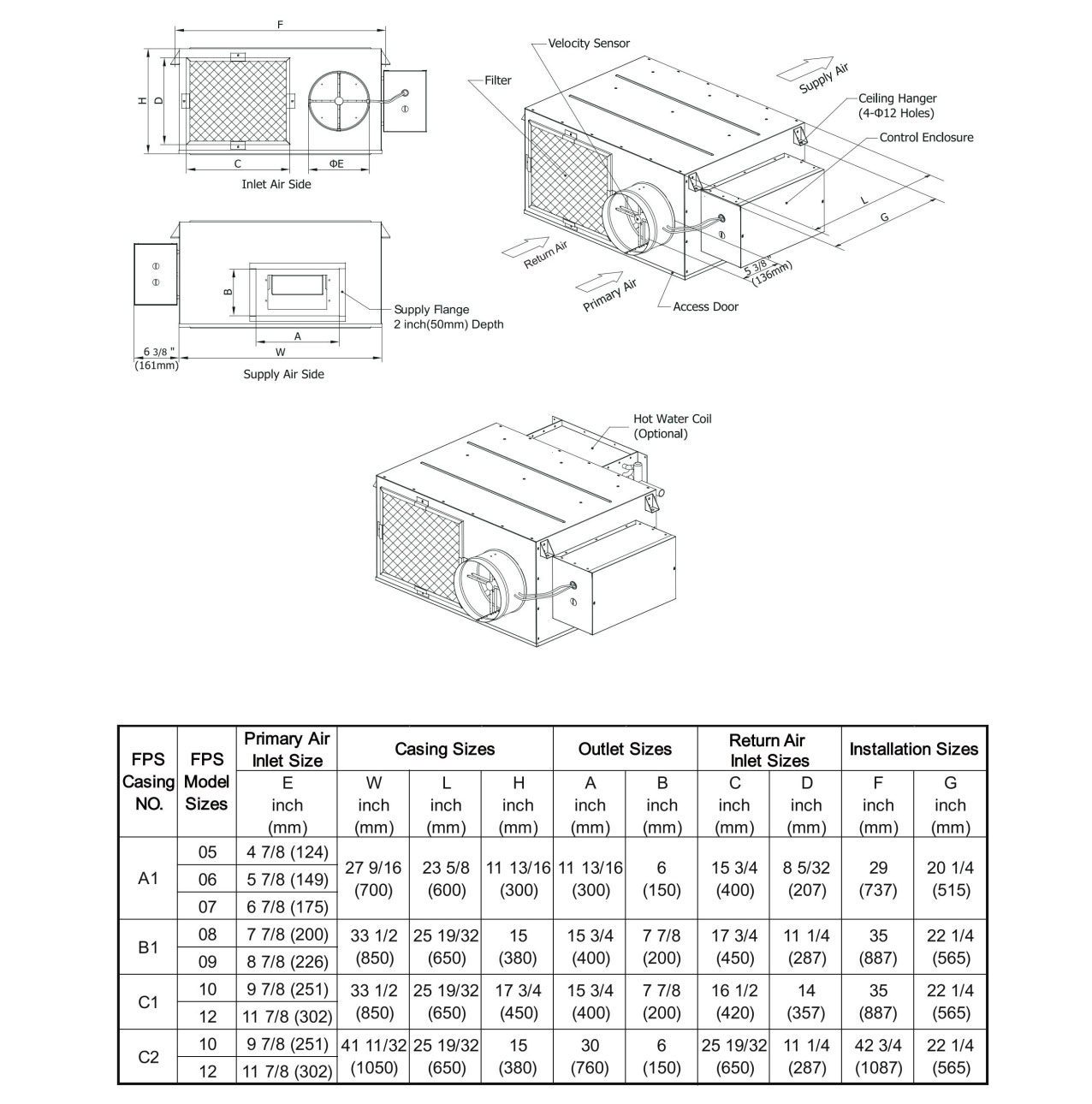

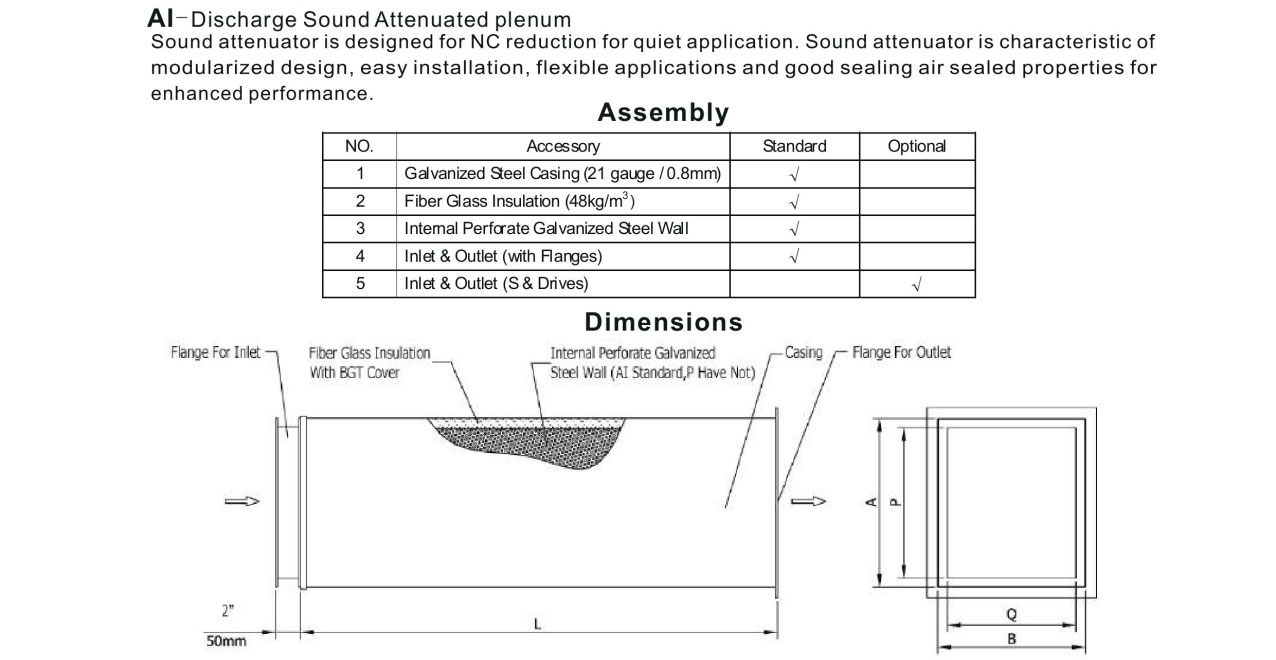

• Provides an advantage to select and design diffusers easily Casing constructed with high quality galvanized steel insulated with batted covered fiber-glass. Inlet flow measured with cross multi-point averaging sensor for pressure Independent terminals.

• High performing low leakage blade damper

Designed for handling low temperature(39°F to 50°F) air in VAV system;

Thermal bridge designed at special points of the unit special lower temperature zone of unit. ( new thermal material at damper's shaft to increase thermal diffusion);

Unit's fan runs continuously, draw the ceiling plenum air into unit to raise supply air temperature to eliminate the risk of condensed water at the diffusers face;

Improved zone air movement.

Provides a advantage to select and design diffusers easily.

Attenuated casing constructed with high quality galvanized steel insulated with batted covered fiber-glass, inlet flow measured with cross multi-point averaging sensor for pressure independent terminals. high performing low leakage blade damper.